Threaded Tee

Teshi Fittings’ Threaded Tees are engineered with meticulous precision to meet rigorous standards across industries like Petroleum, Chemical, Hydraulic, and Food sectors. Each threaded tee is crafted with exacting detail to ensure dependable sealing and seamless integration into piping systems. Committed to excellence and surpassing customer expectations, Teshi Fittings consistently delivers superior durability and performance with every tee. Trust our expertise to tailor solutions for your specific project needs, and experience the unmatched quality of Teshi Fittings’ Threaded Tees for all your piping requirements.

Standard Specification of Threaded Tee

| Threaded Tee Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Threaded Tee Size | 1/8″ NB TO 4″ NB |

| Threaded Tee Type | Threaded, Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

| DIN | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN | EN10253-1, EN10253-2 |

| Threaded Tee Production Grades | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

| Threaded Tee Form | Threaded Tee, Forged Threaded Tee |

Material & Grades of Threaded Tee

| Stainless Steel Threaded Tee | ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L |

| Duplex & Super Duplex Steel Threaded Tee | ASTM A 182 – F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950. |

| Carbon Steel Threaded Tee | ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C |

| Nickel Alloy Threaded Tee | ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276) |

| Alloy Steel Threaded Tee | ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91 |

| Copper Alloy Steel Threaded Tee | ASTM / ASME SB 111 UNS NO. C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 ( CU -NI- 90/10) , C 71500 ( CU -NI- 70/30) |

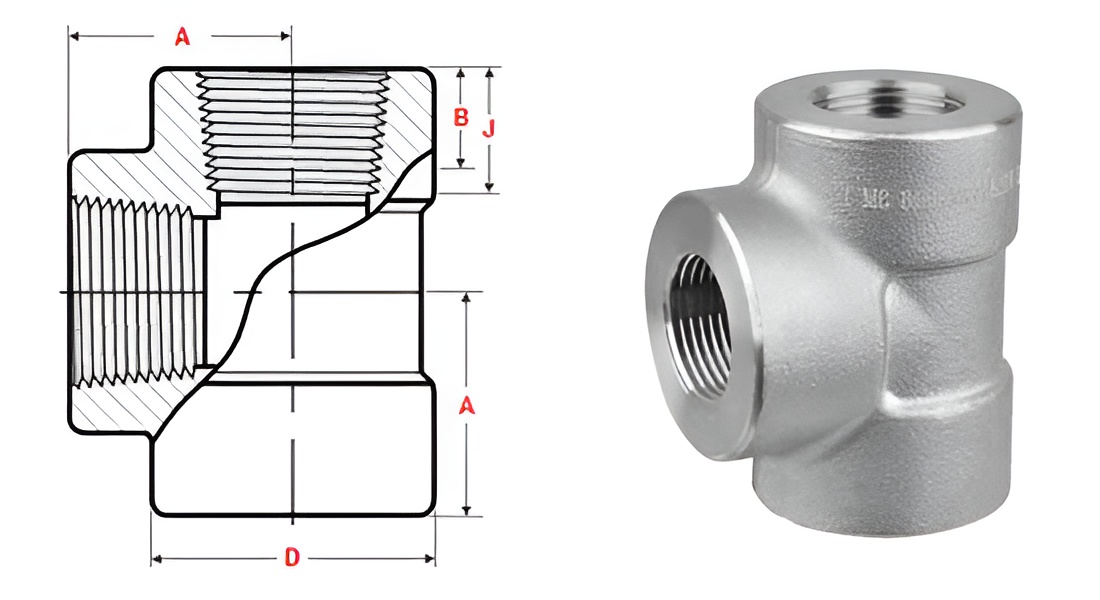

Dimension of Threaded Tee

Threaded Tee Dimensions, 3/4 Threaded Tee Dimensions NPS 1/2 to 4 Class 2000

| NPS | Min Length of Thread | Outside Dia of Band D | Center to End A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3.89 |

| 1.1/2 | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

Threaded Equal Tee Class 3000 Dimensions NPS 1/2 to 4

| NPS | Min Length of Thread | Outside Dia of Band D | Center to End A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

3/4 Threaded Tee Dimensions NPS 1/2 to 4 Class 6000

| NPS | Min Length of Thread | Outside Dia of Band D | Center to End A | Min WT | |

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10.59 |

| 1.1/2 | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

Manufacturing process and features of Threaded Tee

Manufacturing Process:

- Material Selection: Typically crafted from materials such as stainless steel, brass, aluminum, or plastic, chosen based on specific application requirements.

- Turning and Machining: Begins with shaping on a lathe to form the initial cylindrical body of the tee.

- Drilling: Involves precision drilling to create the necessary openings and internal threads essential for the tee’s function.

- Thread Cutting: Threads are meticulously cut into the drilled holes using threading tools or taps, ensuring compatibility and secure fastening.

- Surface Treatment: Often undergoes surface treatments such as plating, coating, or heat treatment to enhance resilience against corrosion, wear, and environmental conditions.

- Quality Control: Rigorous inspection is conducted throughout the manufacturing process to verify dimensional accuracy, thread integrity, and surface finish.

Features of Threaded Tee:

- Threaded Design: Integral for establishing threaded connections between pipes or fittings, accommodating various thread types and sizes.

- Versatility: Adaptable for transitioning between different thread standards (e.g., NPT to BSP) and accommodating diverse pipe diameters.

- Robust Construction: Engineered to endure mechanical stress, corrosion, and wear in diverse operational settings.

- Precision Fit: Threads are meticulously crafted to ensure secure mating with corresponding pipes or fittings.

- Application Specific: Offered in different configurations (e.g., straight, hexagonal, with flanges) to cater to specific plumbing or piping requirements.

- Ease of Installation: Facilitates straightforward assembly and disassembly using standard tools, promoting efficiency in plumbing applications.

By emphasizing these manufacturing processes and key features, one can convey a comprehensive understanding of threaded tee components in mechanical assemblies.

Application Of Threaded Tee

| Oil and Gas | Stainless Steel Forged Threaded Tee – Resistant to corrosion for pipeline systems. |

| Chemical Industry | Forged Threaded Tee – Ensures reliability in corrosive environments. |

| Plumbing | Alloy Steel Threaded Equal Tee – Provides strength in plumbing systems. |

| Heating | Forged Screwed Equal Tee – Used for redirecting flow in heating systems. |

| Water Supply Systems | Threaded Forged Tee – Ensures durable connections in water supply. |

| Power Plant | ANSI B16.11 Forged Threaded Tee – Suitable for high-pressure applications in power plants. |

| Paper & Pulp Industry | Threaded Equal Tee – Resistant to corrosion in paper and pulp processing. |

| General Purpose | Forged Screwed Equal Tee – Versatile fitting for various industrial uses. |

| Fabrication Industry | Forged Threaded Tee – Used in precise fabrication processes. |

| Food Processing | Forged Screwed Equal Tee – Hygienic and durable in food processing. |

| Structural Pipe | Forged Threaded Equal Tee – Provides tight and reliable connections in structural applications. |

Threaded Tee Available Types

| Forged Threaded Tee | Forged Screwed Equal Tees |

| 150 lb. Threaded Fittings Pipe Tee | Threaded Forged Equal Tee |

| ASME B16.11 Forged Threaded Tee | Forged Tee 3000LB Threaded |

| Stainless Steel Screwed Equal Tee | Suppliers SS Forged Threaded Equal Tees |

| ANSI B16.11 Forged Threaded Tee Dealer | BS 3799 Forged Screwed Equal Tee Exporter |

| Forged Threaded Tee Stockholder | Threaded Forged Pipe Tee Distributors |

| Carbon Steel Threaded Equal Tee | High Quality Threaded Tee Manufacturer |

| ASTM A182 Threaded Stainless Steel Tees | Duplex Steel Threaded Equal Tee |

| Super Duplex Steel Screwed Equal Tee | Copper Nickel Threaded Equal Tee |

| High Nickel Alloy Forged Threaded Tee | Hastelloy Screwed Tee Stockist |

| Titanium Forged Threaded Tee | Inconel Threaded Equal Tee |

Others Products

Frequently Asked Questions

Most frequent questions and answers