Reducing Insert

‘Teshi Fittings’ premier Reducing Inserts, meticulously crafted for a range of industries including Petroleum, Chemical, Hydraulic, Food, and beyond. Engineered with precision and manufactured to meet stringent international quality standards, our Reducing Inserts ensure dependable sealing and seamless integration within piping systems. Committed to excellence and exceeding customer expectations, Teshi Fittings guarantees superior performance and longevity in every fitting, offering tailored solutions to meet specific project requirements. Trust in Teshi Fittings’ expertise for all your piping needs and experience the unmatched quality of our Reducing Inserts.

Standard Specification of Reducing Insert

| Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Size | 1/2″NB TO 4″NB IN |

| Type | Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

| DIN | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN | EN10253-1, EN10253-2 |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Form | Socket Weld Fitting Pipe Reducer Insert, 45 Deg Elbow, 90 Deg Elbow, Forged Elbow, Threaded Elbow, Socket Weld Elbow. |

Material & Grades of Reducing Insert

| Stainless Steel Reducing Insert | ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F904L, ASTM A312/A403 TP304, TP304L, TP316, TP316L |

| Duplex & Super Duplex Steel Reducing Insert | ASTM/ASME A182 / SA182, A790 / SA790 UNS No S31803, S32205, ASTM/ASME A182 / SA182, A790 / SA790 UNS No S32750, S32950 |

| Carbon Steel Reducing Insert | ASTM A105, A350 LF2, A106 Gr.B, A234 WPB |

| Low Temperature Carbon Steel Reducing Insert | ASTM/ASME A420 SA/420 WPL3, WPL6 |

| Alloy Steel Reducing Insert | ASTM / ASME A182, ASTM / ASME A335 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91 |

| Nickel Alloy Reducing Insert | ASTM B336, ASME SB336, Nickel 200 (UNS No. No2200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II), Copper Nickel (Cupro-Nickel 90/10 & 70/30). |

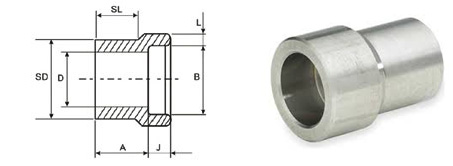

Dimension of Reducing Insert

Dimensions of ASME B 16.11 Socket Weld Reducer Insert

| Class 3000 | Class 6000 | Class 9000 | ||||||||||||

| Nominal Pipe Size | C | D | Fitting Type | A | B | E | Fitting Type | A | B | E | Fitting Type | A | B | E |

| 3/8 x 1/4 | 0.675 | 0.555 | 1 | 7/16 | 3/4 | 15/16 | 1 | 7/16 | 7/8 | 1 | ||||

| 1/2 x 3/8 | 0.850 | 0.690 | 1 | 7/16 | 13/16 | 1 1/16 | 1 | 7/16 | 15/16 | 1 3/16 | ||||

| 1/2 x 1/4 | 0.850 | 0.555 | 1 | 7/16 | 13/16 | 15/16 | 1 | 7/16 | 7/8 | 1 | ||||

| 3/4 x 1/2 | 1.060 | 0.855 | 1 | 7/16 | 7/8 | 1 5/16 | 1 | 7/16 | 1 1/16 | 1 3/8 | 1 | 7/16 | 1 3/16 | 1 3/4 |

| 3/4 x 3/8 | 1.060 | 0.690 | 2 | 7/16 | 5/8 | – | 1 | 7/16 | 7/8 | 1 3/16 | ||||

| 3/4 x 1/4 | 1.060 | 0.555 | 2 | 3/8 | 11/16 | – | 2 | 3/8 | 7/8 | – | ||||

| 1 x 3/4 | 1.325 | 1.065 | 1 | 9/16 | 15/16 | 1 1/2 | 1 | 9/16 | 1 1/8 | 1 11/16 | 1 | 9/16 | 1 1/4 | 2 |

| 1 x 1/2 | 1.325 | 0.855 | 2 | 1/2 | 5/8 | – | 1 | 7/16 | 1 1/8 | 1 3/8 | 1 | 7/16 | 1 1/8 | 1 3/4 |

| 1 x 3/8 | 1.325 | 0.690 | 2 | 7/16 | 11/16 | – | 2 | 1/2 | 7/8 | – | ||||

| 1 x 1/4 | 1.325 | 0.555 | 2 | 3/8 | 3/4 | – | 2 | 3/8 | 15/16 | – | ||||

| 1 1/4 x 1 | 1.670 | 1.330 | 1 | 9/16 | 1 | 1 7/8 | 1 | 9/16 | 1 3/16 | 2 | 1 | 9/16 | 1 3/8 | 2 3/8 |

| 1 1/4 x 3/4 | 1.670 | 1.065 | 2 | 9/16 | 11/16 | – | 2 | 9/16 | 13/16 | – | 1 | 9/16 | 1 3/16 | 2 |

| 1 1/4 x 1/2 | 1.670 | 0.855 | 2 | 1/2 | 3/4 | – | 2 | 1/2 | 7/8 | – | 2 | 1/2 | 7/8 | – |

| 1 1/4 x 3/8 | 1.670 | 0.690 | 2 | 7/16 | 13/16 | – | 2 | 7/16 | 15/16 | – | ||||

| 1 1/4 x 1/4 | 1.670 | 0.555 | 2 | 3/8 | 7/8 | – | 2 | 3/8 | 1 | – | ||||

| 1 1/2 x 1 1/4 | 1.910 | 1.675 | 1 | 9/16 | 1 1/8 | 2 1/4 | 1 | 9/16 | 1 3/8 | 2 3/8 | 1 | 9/16 | 1 5/8 | 2 3/4 |

| 1 1/2 x 1 | 1.910 | 1.330 | 2 | 5/8 | 11/16 | – | 1 | 9/16 | 1 3/16 | 2 | 1 | 9/16 | 1 3/8 | 2 3/8 |

| 1 1/2 x 3/4 | 1.910 | 1.065 | 2 | 9/16 | 3/4 | – | 2 | 9/16 | 1 | – | 2 | 9/16 | 1 | – |

| 1 1/2 x 1/2 | 1.910 | 0.855 | 2 | 1/2 | 13/16 | – | 2 | 1/2 | 1 1/16 | – | 2 | 9/16 | 1 | – |

| 1 1/2 x 3/8 | 1.910 | 0.690 | 2 | 7/16 | 7/8 | – | 2 | 7/16 | 1 1/8 | – | ||||

| 2 x 1 1/2 | 2.385 | 1.915 | 1 | 9/16 | 1 1/4 | 2 1/2 | 1 | 9/16 | 1 7/8 | 2 11/16 | 1 | 9/16 | 2 1/16 | 3 |

| 2 x 1 1/4 | 2.385 | 1.675 | 2 | 11/16 | 13/16 | – | 2 | 7/8 | 15/16 | – | 1 | 9/16 | 2 | 2 3/4 |

| 2 x 1 | 2.385 | 1.330 | 2 | 5/8 | 7/8 | – | 2 | 13/16 | 1 | – | 2 | 13/16 | 1 | – |

| 2 x 3/4 | 2.385 | 1.065 | 2 | 9/16 | 15/16 | – | 2 | 3/4 | 1 1/16 | – | 2 | 3/4 | 1 1/16 | – |

| 2 x 1/2 | 2.385 | 0.855 | 2 | 1/2 | 1 | – | 2 | 11/16 | 1 1/8 | – | 2 | 11/16 | 1 1/8 | – |

Manufacturing process and features of Reducing Insert

Manufacturing Process:

- Material Selection: Choose from stainless steel, carbon steel, or alloy steel based on specific application requirements.

- Material Preparation: Shape sheets, plates, or rods through cutting, shaping, or molding.

- Forming: Utilize forging, casting, or machining methods to achieve the insert’s shape and dimensions.

- End Preparation: Prepare ends for fittings or welding as per design requirements.

- Surface Finishing: Polish, grind, or coat surfaces for enhanced durability and corrosion resistance.

- Quality Control: Conduct rigorous inspections to ensure dimensional accuracy and adherence to performance standards.

- Packaging: Securely package inserts after final inspection for safe distribution.

Features of Reducing Insert:

- Functionality: Facilitates smooth transitions between pipes of different sizes or types within piping systems.

- Materials and Pressure Rating: Available in various materials with suitable pressure ratings.

- Leak Resistance: Ensures reliable sealing to prevent leaks when properly installed.

- Durability: Resistant to corrosion, wear, and environmental factors for extended service life.

- Versatility: Offered in multiple sizes, configurations, and materials to meet diverse application needs.

- Ease of Installation: Simple to install using standard piping practices and equipment.

- Cost-Effectiveness: Provides economical solutions for adapting and optimizing piping systems.

Application Of Reducing Insert

| Chemical and Petrochemical Processing | Ensures secure pipe connections for chemical and petrochemical transport. |

| Refineries | Essential for joining pipes carrying refined products and fuels. |

| Electronics | Used in piping systems for cooling or process fluids in electronics manufacturing. |

| Fertilizer | Connects pipes handling chemicals and liquids in fertilizer production. |

| Power Plants (including Nuclear Power) | Critical for piping systems in conventional and nuclear power plants for fluid transport. |

| Oil and Gas | Essential in oil and gas operations for joining pipes under various conditions. |

| Paper Industries | Used in piping systems for water supply, chemicals, and other fluids in paper manufacturing. |

Reducing Insert Available Types

| Forged Threaded Reducing Insert | Threaded Reducing Half Insert |

|---|---|

| 2000LBS Threaded Reducing Insert Fittings | 6000LBS Forged Threaded Reducing Insert |

| ASME B16.11 Forged Threaded Pipe Reducing Insert | Threaded Forged Reducing Insert 3000LBS |

| ASME B16.11 Reducing Insert Threaded – Class 3000 | SS Forged Threaded Reducing Insert |

| ANSI B16.11 Forged Threaded Reducing Insert | BS 3799 Forged Screwed Reducing Insert |

| Carbon Steel Threaded Reducing Insert Supplier | High Quality Threaded Reducing Insert Manufacturer |

| ASTM A182 Threaded Reducing Insert | Duplex Steel Threaded Reducing Insert |

| Super Duplex Steel Screwed Reducing Insert | Copper Nickel Threaded Reducing Insert |

| High Nickel Alloy Threaded Reducing Insert | Hastelloy Screwed Reducing Insert Pipe Fittings |

| Titanium Forged Threaded Reducing Insert | Inconel Threaded Forged Reducing Insert |

Others Products

Frequently Asked Questions

Most frequent questions and answers