Reducing Flange

Teshi Fittings, a premier manufacturer of pipe fittings, offers high-quality Reducing Flanges designed for various industries including Petroleum, Chemical, Hydraulic, Food, and more. Crafted with meticulous precision and adherence to international quality standards, our Reducing Flanges provide efficient solutions for connecting pipes of different sizes in piping systems. With a commitment to excellence and customer satisfaction, Teshi Fittings delivers superior performance and durability in every flange, offering tailored solutions to meet specific project requirements. Experience the difference with Teshi Fittings’ Reducing Flanges and trust in our expertise for all your piping needs.

Standard Specification of Reducing Flange

| Standards / Dimensions | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, BS, GOST, MSS SP-44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605 |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Flange Face Types / Connection Type | Flat Face Flange (FF), Raised Face Flange (RF), Ring Joint Flange (RTJ), Lap Joint Flange, Male and Female Flange (M&F), Large and Small Tongue-and-Groove Flange (T&G) |

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, ASA, API-605, MSS SP44, AWWA, Custom Drawings |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

Material & Grades of Reducing Flange

| Stainless Steel | ASTM/ASME A/SA182:- F304, F304L, F316, F316L, ASTM/ASME A/SA351:- CF3, CF3M, CF8, CF8M, DIN 1.4306, DIN 1.4301, DIN 1.4404, DIN 1.4401, DIN 1.4408, DIN 1.4308, DIN 1.4306, DIN 1.4409 |

| Duplex & Super Duplex Steel | S31803 / S32205 A182:- Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 S32750 / S32760 A182:- Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Carbon Steel | ASTM/ASME A/SA105 A/SA105N and A/SA216-WCB, DIN 1.0460, DIN 1.0402, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, CS High Yield ASTM A694 / A694 (F52, F56, F60, F65, F70, F80) |

| Low Temperature Carbon Steel | ASTM A350, LF2, LF3 |

| Alloy Steel | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Nickel Alloy | Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II) |

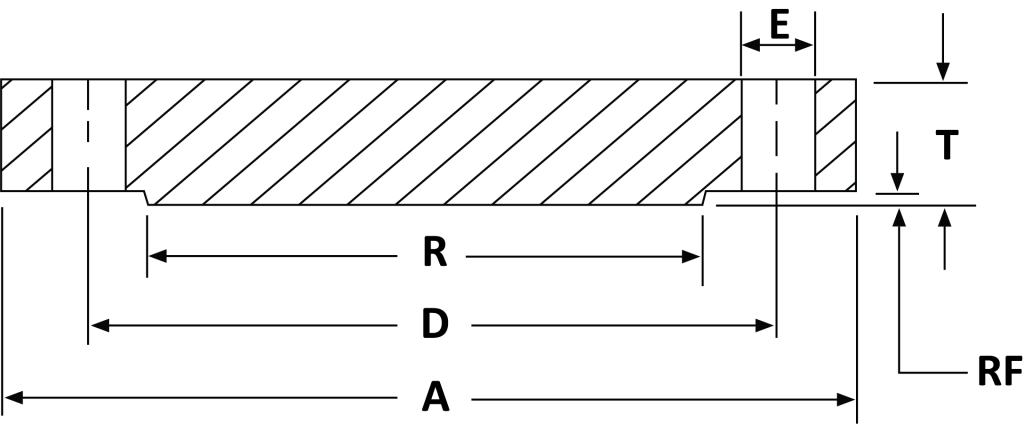

Dimension of Reducing Flange

| Nominal Size | Type | Ø A | D | Liner Thickness | |

|---|---|---|---|---|---|

| DN1 | DN2 | ||||

| In. | In. | mm | mm | mm | |

| 3/4″ | 1/2″ | 1 | 98.5 | 30 | 5.0 |

| 1″ | 1/2″ | 1 | 108 | 30 | 5.0 |

| 1″ | 3/4″ | 1 | 108 | 30 | 5.0 |

| 1.1/2″ | 1/2″ | 1 | 127 | 30 | 5.0 |

| 1.1/2″ | 3/4″ | 1 | 127 | 30 | 5.0 |

| 1.1/2″ | 1″ | 1 | 127 | 30 | 5.0 |

| 2″ | 1/2″ | 3 | 152 | 30 | 5.0 |

| 2″ | 3/4″ | 2 | 152 | 30 | 5.0 |

| 2″ | 1″ | 2 | 152 | 30 | 5.0 |

| 2″ | 1.1/2″ | 1 | 152 | 30 | 5.0 |

| 3″ | 3/4″ | 3 | 190.5 | 35 | 5.0 |

| 3″ | 1″ | 3 | 190.5 | 35 | 5.0 |

| 3″ | 1.1/2″ | 2 | 190.5 | 35 | 5.0 |

| 3″ | 2″ | 1 | 190.5 | 35 | 5.0 |

| 4″ | 3/4″ | 3 | 228.6 | 35 | 5.0 |

| 4″ | 1″ | 3 | 228.6 | 35 | 5.0 |

| 4″ | 1.1/2″ | 3 | 228.6 | 35 | 5.0 |

| 4″ | 2″ | 3 | 228.6 | 35 | 5.0 |

| 4″ | 3″ | 2 | 228.6 | 35 | 5.0 |

| 6″ | 3/4″ | 3 | 280 | 40 | 5.0 |

| 6″ | 1″ | 3 | 280 | 40 | 5.0 |

| 6″ | 1.1/2″ | 3 | 280 | 40 | 5.0 |

| 6″ | 2″ | 3 | 280 | 40 | 5.0 |

| 6″ | 3″ | 3 | 280 | 40 | 5.0 |

| 6″ | 4″ | 2 | 280 | 40 | 5.0 |

| 8″ | 1″ | 3 | 343 | 35 | 5.0 |

| 8″ | 1.1/2″ | 3 | 343 | 35 | 5.0 |

| 8″ | 2″ | 3 | 343 | 40 | 5.0 |

| 8″ | 3″ | 3 | 343 | 40 | 5.0 |

| 8″ | 4″ | 3 | 343 | 40 | 5.0 |

| 8″ | 6″ | 2 | 343 | 40 | 5.0 |

| 10″ | 1″ | 3 | 406 | 35 | 2.5 |

| 10″ | 1.1/2″ | 3 | 406 | 35 | 2.5 |

| 10″ | 2″ | 3 | 406 | 35 | 2.5 |

| 10″ | 3″ | 3 | 406 | 35 | 2.5 |

| 10″ | 4″ | 3 | 406 | 35 | 2.5 |

| 10″ | 6″ | 3 | 406 | 35 | 2.5 |

| 10″ | 8″ | 2 | 406 | 35 | 3.5 |

| 12″ | 1″ | 3 | 483 | 35 | 3.5 |

| 12″ | 1.1/2″ | 3 | 483 | 35 | 3.5 |

| 12″ | 2″ | 3 | 483 | 35 | 3.5 |

| 12″ | 3″ | 3 | 483 | 35 | 3.5 |

| 12″ | 4″ | 3 | 483 | 35 | 3.5 |

| 12″ | 6″ | 3 | 483 | 35 | 3.5 |

| 12″ | 8″ | 3 | 483 | 35 | 3.5 |

| 12″ | 10″ | 2 | 483 | 35 | 3.5 |

| 14″ | 12″ | 1 | 533 | 40 | 3.5 |

| 16″ | 12″ | 3 | 597 | 40 | 3.5 |

| 16″ | 14″ | 2 | 597 | 35 | 3.5 |

Manufacturing process and features of Reducing Flange

Manufacturing Process:

- Material Selection : Choose suitable materials such as carbon steel, stainless steel, or alloy steel based on application requirements.

- Cutting : Cut the raw material into the required shapes and sizes using cutting machines or torches.

- Forging : Heat the material and forge it into the flange shape, ensuring it meets the specifications for the larger and smaller diameters of the reducing flange.

- Forming : Form the flange to achieve the desired dimensions and thickness, accommodating the reduction in size from one end to the other.

- Machining : Machine the flange to precise tolerances using CNC machines, ensuring smooth surfaces and accurate dimensions. This includes creating the bolt holes and ensuring the flange faces are flat and aligned.

- Drilling Bolt Holes : Drill bolt holes into the flange according to standards such as ANSI B16.5 or customer specifications, ensuring proper alignment for connection with mating flanges.

- Surface Finishing : Perform surface treatments such as grinding, polishing, or coating to enhance corrosion resistance and aesthetics.

- Inspection and Testing : Conduct thorough inspection and testing, including dimensional checks and non-destructive testing (NDT) methods like ultrasonic testing, to ensure quality and reliability.

- Marking and Packaging : Mark the reducing flange with relevant information such as material grade, size, pressure rating, and standards compliance. Package the flanges carefully to protect them during transportation.

Features of Reducing Flange :

- Size Reduction : Designed to connect pipes of different diameters, facilitating a seamless transition between larger and smaller pipes in a piping system.

- Versatility : Suitable for a wide range of applications and industries where size transitions in piping are required, such as oil and gas, chemical processing, and water treatment.

- Ease of Installation : Allows for straightforward installation and alignment, ensuring a secure connection between pipes of varying sizes.

- Pressure Ratings : Available in various pressure ratings to suit different industrial applications, from low to high-pressure systems.

- Corrosion Resistance : Manufactured in materials with excellent corrosion resistance properties, ensuring durability in harsh environments.

- Standards Compliance : Designed and manufactured in compliance with international standards (e.g., ANSI, ASME, ASTM) to ensure quality, reliability, and compatibility with other flange components.

- Cost-Effective Solution : Offers a cost-effective method for reducing pipe size within a piping system, eliminating the need for additional fittings or adaptors.

- Wide Range of Sizes : Available in a variety of sizes to accommodate different pipe diameters and system requirements.

- Structural Integrity : Provides a robust and reliable connection that maintains the structural integrity of the piping system.

Application Of Reducing Flange

| Oil and Gas Industry | Used in pipelines and refineries to connect pipes of varying sizes, facilitating efficient transport of oil, gas, and other hydrocarbons. Essential for managing flow rates and pressures in complex pipeline networks. |

| Chemical Processing | Utilized in chemical plants where different pipe sizes are needed to handle various chemical substances, ensuring proper flow and preventing leaks in corrosive environments. |

| Power Generation | Found in power plants to connect different sections of piping systems, ensuring efficient flow of water, steam, or other fluids. Used in both fossil fuel and nuclear power plants to manage different flow requirements. |

| Water Treatment | Used in water treatment facilities to connect pipes of different diameters, ensuring smooth and efficient water flow. Essential for managing different stages of water purification and distribution. |

| Pulp and Paper Industry | Facilitates transitions in pipelines within paper mills and pulp processing facilities, where varying pipe sizes are common to handle different processing stages and fluid types. |

| Food and Beverage Processing | Enables smooth transitions in piping systems used for processing and transporting food and beverage products. Helps in maintaining hygiene and preventing contamination. |

| Pharmaceutical Industry | Used in pharmaceutical manufacturing facilities to connect pipes of varying diameters while maintaining sterile conditions. Ensures precise flow control and cleanliness. |

| Mining and Mineral Processing | Facilitates connections in pipelines used for transporting minerals and ores in mining operations. Helps in managing flow rates and handling abrasive materials. |

| Construction and Infrastructure | Found in building HVAC (heating, ventilation, and air conditioning) systems and municipal infrastructure projects for efficient fluid distribution. Used in connecting different pipe sizes in plumbing and drainage systems. |

| Shipbuilding and Marine Applications | Used in shipbuilding for piping systems where different pipe sizes need to be connected to ensure efficient operation at sea. Essential for managing various fluids and gases in marine environments. |

| General Industrial Applications | Employed in various industrial applications where pipe size reduction is needed to accommodate different equipment, flow rates, or system requirements. |

Reducing Flange Available Types

| Reducing Flange | Reducing Flange Threaded |

| Stainless Steel Reducing Flange | Forged Steel Raised Face Reducing Flange |

| Carbon Steel Reducing Flange | ANSI B16.47 Reducing Flange |

| Alloy Steel Reducing Flange | Class 150 LBS Reducing Flange Stockiests |

| Nickel Alloy Reducing Flange | MSS SP44 Reducing Flange |

| Inconel Reducing Flange | Class 300 LBS Reducing Flange |

| Alloy Steel Reducing Flange Exporters | Class 600 LBS Reducing Flange |

| Duplex Steel Reducing Flange | DIN / EN Reducing Flange Manufacturers |

| Titanium Alloy Reducing Flange | ASME / ANSI B16.5 Reducing Threaded Flange |

| Super Duplex Steel Reducing Threaded Flange | ANSI / ASME Reducing Flange Suppliers |

| Copper Nickel Reducing Flange | High Quality Reducing Flange Exporters |

Others Products

Frequently Asked Questions

Most frequent questions and answers