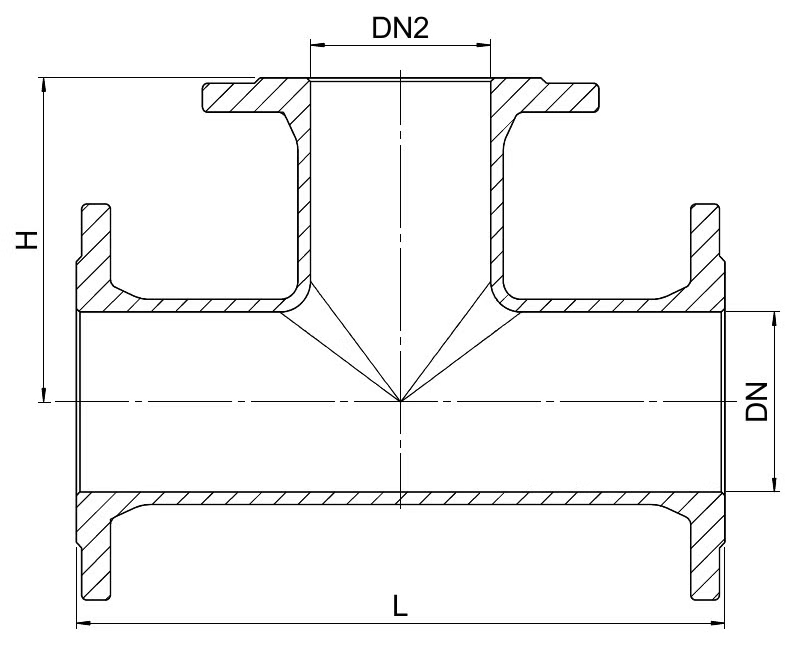

Flanged Tee

Teshi Fittings, a premier manufacturer of pipe fittings, offers high-quality Flanged Tees designed for various industries including Petroleum, Chemical, Hydraulic, Food, and more. Engineered with meticulous precision and adherence to international quality standards, our Flanged Tees provide efficient and reliable branching connections in piping systems. With a commitment to excellence and customer satisfaction, Teshi Fittings delivers superior performance and durability in every fitting, offering tailored solutions to meet specific project requirements. Experience the difference with Teshi Fittings’ Flanged Tees and trust in our expertise for all your piping needs.

Standard Specification of Flanged Tee

| Flanges Types | Slip On, Weld Neck, Long Weld Neck, Threaded, Blind, Companion, Lap Joint. |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS ASA 150, ASA 300, PN 6,10,16,25, 40,64,100,160 ETC. available with NACE MR 01-75 |

| Size | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Types | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ), Lap-Joint Face (LJF), Large Male-Female (LMF), Small Male-Female (SMF), Large Tongue & Groove, Small Tongue, Groove |

Material & Grades of Flanged Tee

| Stainless Steel | ASTM /ASME A/SA 213 / 249 / 269 / 312 / 358 CL. I to V – 304 , 304L , 304H, 309S ,309H , 310S, 310H , 316 , 316TI , 316H , 316 LN , 317 , 317L , 321 , 321H , 347 , 347 H , 904L |

| Duplex Steel | ASTM/ASME A/SA 789, 790 – UNS NO S 31803, S 32205, S 32550, S 32750, S 32760. |

| Carbon Steel | ASTM A106 Gr. A, B & C API 5L Gr. A / B, X42 ,X52 ,X60 ASTM A 53 Gr. A/B |

| Alloys Steel | ASTM /ASME A/SA 213 / 335 / 691 – P5,P9,P11,P12,P22,P91 |

| Nickel Alloy | Nickel Alloys 200, Nickel Alloys 201 |

| Hastelloy | Hastelloy C-22, Hastelloy C-276, Hastelloy C-2000, Hastelloy C-4, Hastelloy X, Hastelloy B, Hastelloy N, Hastelloy G |

| Inconel | Inconel 600, Inconel 601, Inconel 625, Inconel 625LCF, Inconel 686, Inconel 718, Inconel 800, Inconel 825, Inconel X-750 , Inconel 690, Inconel 602, Inconel 617, Inconel 925, Inconel A-289, Inconel AL-6XN, AL-904L |

Dimension of Flanged Tee

Manufacturing process and features of Flanged Tee

Manufacturing Process:

- Material Selection : The appropriate materials such as carbon steel, stainless steel, or alloy steel are chosen based on application requirements and industry standards.

- Cutting : The material is cut into the required size using precise cutting techniques to ensure accurate dimensions.

- Forming : The tee shape is formed using processes such as forging, casting, or machining. This involves creating a T-shaped configuration with the main pipe and a branch at a right angle.

- Flanging : Flanges are attached to the ends of the tee. This is done either by welding the flanges onto the ends or by forming the flanges integrally with the tee.

- Welding : If the flanges are welded, high-quality welding processes are employed to ensure strong, leak-free joints. Non-destructive testing methods may be used to inspect the welds.

- Heat Treatment : The flanged tee may undergo heat treatment processes such as annealing or normalizing to enhance its mechanical properties and ensure strength and durability.

- Surface Treatment : Surface treatments such as galvanizing, painting, or applying protective coatings are done to protect the tee from corrosion and other environmental factors.

- Inspection and Testing : The finished product is subjected to rigorous inspection and testing to ensure it meets all dimensional, mechanical, and quality specifications. This includes pressure testing, X-ray inspection, and dimensional checks.

Features of Flanged Tee :

- Versatile Connection : Provides a right-angle branch in piping systems, facilitating versatile and flexible design.

- Flanged Ends : Enables easy assembly and disassembly, which simplifies maintenance and inspection of the piping system.

- High Strength and Durability : Manufactured from robust materials, ensuring the flanged tee can withstand high pressure and temperature conditions.

- Corrosion Resistance : Surface treatments and material choices provide resistance to corrosion, extending the tee’s service life in harsh environments.

- Standard Compliance : Manufactured according to industry standards such as ASME, ANSI, and API, ensuring compatibility and reliability in various applications.

- Leak-Free Connection : Precision manufacturing and quality control measures ensure a leak-free connection, crucial for maintaining system integrity and safety.

- Wide Range of Sizes : Available in various sizes and pressure ratings to suit different piping system requirements.

- Ease of Installation : Designed for easy installation, reducing labor and time during assembly.

Flanged tees are vital components in various industries, providing a reliable and versatile solution for branching pipelines. Their manufacturing process ensures high strength, durability, and compliance with industry standards. Flanged tees are widely used in oil and gas, chemical processing, water treatment, power generation, and many other applications where secure and efficient fluid distribution is essential.

Application Of Flanged Tee

| Oil and Gas Industry | Used in pipeline systems for transporting crude oil, natural gas, and refined products. Facilitates branching of main pipelines to distribute products to different processing units or storage facilities. |

| Chemical Processing | Essential in chemical plants for handling corrosive chemicals and fluids. Provides reliable connections for various process streams and distribution lines within the plant. |

| Water Treatment | Utilized in water treatment plants for distributing treated water to different sections. Helps in connecting pipelines carrying chemicals, clean water, and wastewater. |

| Power Generation | Applied in power plants for connecting steam, water, and fuel lines. Ensures efficient distribution of fluids in boiler systems, cooling towers, and other equipment. |

| Petrochemical Industry | Integral in petrochemical plants for transporting hydrocarbons and chemical mixtures. Facilitates the branching of pipelines to various processing units and storage tanks. |

| HVAC Systems | Used in heating, ventilation, and air conditioning systems for distributing heating and cooling fluids. Ensures efficient flow and distribution in large commercial and industrial buildings. |

| Food and Beverage Processing | Essential in food processing plants for transporting food-grade fluids and ingredients. Provides hygienic and secure connections in sanitary piping systems. |

| Pharmaceutical Industry | Used in pharmaceutical manufacturing for handling sterile fluids and ingredients. Ensures clean and contamination-free connections in critical process pipelines. |

| Marine and Offshore | Applied in marine and offshore environments for distributing fluids on ships, oil platforms, and drilling rigs. Provides durable and corrosion-resistant connections in harsh sea conditions. |

| Fire Protection Systems | Integral part of fire protection systems for distributing water or fire-suppressant fluids. Ensures reliable connections in sprinkler systems and fire hydrant networks. |

| Mining Industry | Used in mining operations for transporting slurry, water, and chemicals. Provides robust connections in abrasive and corrosive environments. |

| General Industrial Applications | Utilized in various industrial applications for distributing fluids and gases in manufacturing processes. Ensures flexible and reliable connections in complex piping networks. |

Frequently Asked Questions

Most frequent questions and answers