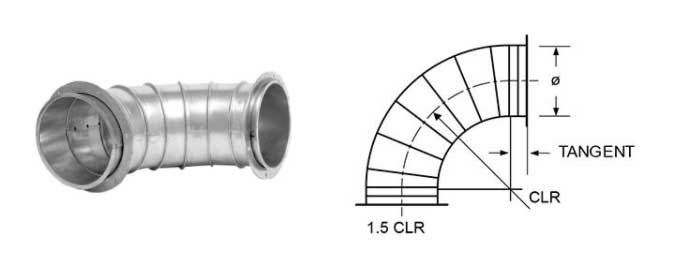

Flanged Elbow

Teshi Fittings, a leading manufacturer of pipe fittings, offers top-quality Flanged Elbows designed for a variety of industries, including Petroleum, Chemical, Hydraulic, Food, and more. Precisely engineered and meeting international quality standards, our Flanged Elbows ensure efficient directional changes in piping systems. Committed to excellence and customer satisfaction, Teshi Fittings provides durable and high-performance solutions tailored to meet your specific project requirements. Discover the superior quality and reliability of Teshi Fittings’ Flanged Elbows and trust our expertise for all your piping needs.

Standard Specification of Flanged Elbow

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, ASA, API-605, MSS SP44, AWWA, Custom Drawings |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Flange Face Types / Connection Type | Flat Face Flange (FF), Raised Face Flange (RF), Ring Joint Flange (RTJ), Lap Joint Flange, Male and Female Flange (M&F), Large and Small Tongue-and-Groove Flange (T&G) |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

| Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

Material & Grades of Flanged Elbow

| Stainless Steel | ASTM A-479, A-182, 304, 304L,304H,304S, 316, 316L,316 Ti, 316H, 309, 310, 310S, 317L, 321, 347, 409, 410, 420, 430, 440, 446, 904L. etc. |

| Duplex & Super Duplex Steel | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 & ASTM / ASME A/SA 182, A240 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Carbon Steel | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Low Temperature Carbon Steel | ASTM A350, LF2, LF3 |

| Alloy Steel | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Nickel Alloy | Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II) |

Dimension of Flanged Elbow

| Size in. | CLR Std. | OD in. | ID in. | Weight (lbs.) | Flange | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30° | 45° | 60° | 90° | Hgt. (H) in. | Thk. (T) in. | ID in. | B.C. in. | OD in. | Bolts # | Hole Dia. in. | ||||

| 3 | 1 | 3.07 | 3.00 | 1.60 | 1.75 | 1.60 | 1.75 | 1.00 | 0.1250 | 3.06 | 4.31 | 5.06 | 6 | 0.281 |

| 4 | 1 | 3.89 | 3.82 | 2.00 | 2.25 | 2.00 | 2.25 | 1.00 | 0.1250 | 4.06 | 5.31 | 6.06 | 6 | 0.281 |

| 5 | 1 | 4.91 | 4.84 | 2.75 | 2.80 | 2.75 | 2.80 | 1.00 | 0.1250 | 5.06 | 6.31 | 7.06 | 6 | 0.281 |

| 6 | 1 | 5.93 | 5.86 | 3.65 | 3.85 | 3.65 | 3.85 | 1.25 | 0.1250 | 6.09 | 7.31 | 8.91 | 6 | 0.281 |

| 7 | 1 | 6.94 | 6.87 | 4.80 | 4.90 | 4.80 | 4.90 | 1.25 | 0.1250 | 7.13 | 8.50 | 9.63 | 6 | 0.375 |

| 8 | 1.5 | 7.93 | 7.86 | 6.87 | 7.66 | 6.87 | 7.66 | 1.25 | 0.1250 | 8.13 | 9.56 | 10.63 | 6 | 0.375 |

| 9 | 1.5 | 8.92 | 8.85 | 9.48 | 8.45 | 9.48 | 8.45 | 1.25 | 0.1250 | 9.13 | 10.63 | 11.63 | 6 | 0.438 |

| 10 | 1.5 | 9.93 | 9.86 | 12.98 | 15.47 | 12.98 | 15.47 | 1.25 | 0.1250 | 10.13 | 11.81 | 12.63 | 6 | 0.438 |

| 11 | 1.5 | 10.92 | 10.85 | 15.49 | 17.60 | 15.49 | 17.60 | 1.25 | 0.1250 | 11.13 | 12.75 | 13.63 | 6 | 0.438 |

| 12 | 1.5 | 11.99 | 11.92 | 18.67 | 19.33 | 18.67 | 19.33 | 1.50 | 0.1250 | 12.13 | 14.00 | 15.13 | 8 | 0.438 |

| 13 | 1.5 | 13.00 | 12.92 | 21.44 | 22.40 | 21.44 | 22.40 | 1.50 | 0.1250 | 13.13 | 15.00 | 16.13 | 8 | 0.438 |

| 14 | 1.5 | 13.99 | 13.91 | 24.92 | 25.39 | 24.92 | 25.39 | 1.50 | 0.1250 | 14.13 | 16.00 | 17.13 | 8 | 0.438 |

| 15 | 1.5 | 14.99 | 14.91 | 27.80 | 27.90 | 27.80 | 27.90 | 1.50 | 0.1250 | 15.13 | 17.00 | 18.13 | 8 | 0.438 |

| 16 | 1.5 | 16.00 | 15.92 | 30.25 | 30.51 | 30.25 | 30.51 | 1.50 | 0.1875 | 16.13 | 18.00 | 19.13 | 8 | 0.438 |

| 17 | 1.5 | 17.00 | 16.92 | 33.69 | 32.30 | 33.69 | 32.30 | 1.50 | 0.1875 | 17.13 | 19.00 | 20.13 | 8 | 0.438 |

| 18 | 1.5 | 17.99 | 17.91 | 36.86 | 34.67 | 36.86 | 34.67 | 1.50 | 0.1875 | 18.13 | 20.00 | 21.13 | 8 | 0.438 |

| 20 | 1.5 | 20.00 | 19.92 | 40.52 | 41.99 | 40.52 | 41.99 | 1.50 | 0.1875 | 20.13 | 21.75 | 23.13 | 12 | 0.438 |

| 22 | 1.5 | 22.01 | 21.93 | 45.95 | 46.90 | 45.95 | 46.90 | 1.50 | 0.1875 | 22.13 | 23.75 | 25.13 | 12 | 0.438 |

| 24 | 1.5 | 23.98 | 23.9 | 58.95 | 70.96 | 58.95 | 70.96 | 1.50 | 0.1875 | 24.13 | 25.88 | 27.13 | 12 | 0.438 |

| 26 | 1.5 | 26.07 | 25.94 | 75.08 | 89.12 | 75.08 | 89.12 | 2.00 | 0.1875 | 26.13 | 28.38 | 30.13 | 16 | 0.438 |

| 28 | 1.5 | 28.07 | 27.94 | 82.97 | 99.19 | 82.97 | 99.19 | 2.00 | 0.1875 | 28.13 | 30.38 | 32.13 | 16 | 0.438 |

| 30 | 1.5 | 30.06 | 29.94 | 91.71 | 110.26 | 91.71 | 110.26 | 2.00 | 0.1875 | 30.13 | 32.38 | 34.13 | 16 | 0.438 |

| 32 | 1.5 | 32.06 | 31.94 | 100.23 | 121.38 | 100.23 | 1.38 | 2.00 | 0.1875 | 32.13 | 34.38 | 36.13 | 16 | 0.438 |

| 34 | 1.5 | 33.93 | 33.06 | 132.18 | 133.52 | 132.18 | 133.52 | 2.00 | 0.1875 | 34.13 | 36.38 | 38.13 | 16 | 0.438 |

| 36 | 1.5 | 36.06 | 35.93 | 122.29 | 149.04 | 122.29 | 149.04 | 2.00 | 0.1875 | 36.13 | 38.38 | 40.13 | 16 | 0.438 |

| 38 | 1.5 | 38.08 | 37.94 | 132.58 | 162.31 | 132.58 | 162.31 | 2.00 | 0.1875 | 38.13 | 40.38 | 42.13 | 24 | 0.438 |

| 40 | 1.5 | 40.08 | 39.94 | 142.99 | 176.20 | 142.99 | 176.20 | 2.00 | 0.1875 | 40.13 | 42.38 | 44.13 | 24 | 0.438 |

Manufacturing process and features of Flanged Elbow

Manufacturing Process of Flanged Elbow :

Material Selection:

- Choose high-quality materials such as stainless steel, carbon steel, or alloy steel, depending on the application requirements.

Cutting and Forming:

- The material is cut to the required length using advanced cutting machinery.

- The cut piece is then formed into an elbow shape using a bending machine or a hydraulic press. The bending process ensures the correct angle and curvature of the elbow.

Flange Formation:

- Flanges are manufactured separately through processes like forging or casting.

- The flange faces are machined to ensure a smooth, precise surface that will mate properly with other flanged components.

Welding:

- The formed elbow and the flanges are joined together using a welding process such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding.

- Welding ensures a strong, leak-proof connection between the elbow and the flanges.

Heat Treatment:

- After welding, the flanged elbow undergoes heat treatment to relieve stress and enhance mechanical properties like strength and durability.

- Heat treatment processes include annealing, normalizing, and quenching, depending on the material and application requirements.

Machining:

- The flanged elbow is machined to achieve precise dimensions and tolerances.

- Machining includes turning, milling, drilling, and grinding to ensure the elbow meets the specified standards.

Surface Treatment:

- Surface treatments such as pickling, passivation, or coating (e.g., galvanizing) are applied to enhance corrosion resistance and improve the aesthetic appearance.

- Surface treatments also ensure the flanged elbow can withstand harsh environments.

Inspection and Testing:

- The flanged elbow undergoes rigorous inspection and testing to ensure it meets the required standards and specifications.

- Tests include visual inspection, dimensional checks, pressure testing, and non-destructive testing (NDT) methods like ultrasonic testing or radiographic testing.

Finishing:

- Final finishing processes include polishing and marking the flanged elbow with relevant details such as size, material, and standards.

- The finished product is then cleaned and prepared for packaging.

Features of Flanged Elbow:

Angular Diversion:

- Flanged elbows are designed to change the direction of fluid flow in a piping system, typically at angles of 45°, 90°, or 180°.

Strong Connection:

- The welded connection between the elbow and flanges ensures a robust, leak-proof joint, suitable for high-pressure applications.

Corrosion Resistance:

- Depending on the material and surface treatment, flanged elbows offer excellent resistance to corrosion, making them suitable for various environments.

High Pressure and Temperature Tolerance:

- Flanged elbows are engineered to withstand high pressures and temperatures, making them ideal for demanding industrial applications.

Ease of Installation:

- The flanged ends facilitate easy installation and alignment with other flanged components, reducing installation time and effort.

Versatility:

- Available in a variety of materials, sizes, and configurations to suit different applications and requirements.

Dimensional Accuracy:

- Manufactured to precise dimensions and tolerances to ensure compatibility with other piping components and systems.

Customization:

- Flanged elbows can be customized to meet specific requirements, such as unique angles, special coatings, or additional features.

Leak-Proof:

- The flanged connection ensures a secure, leak-proof joint, essential for maintaining system integrity and safety.

Flanged elbows are critical components in piping systems, providing reliable and durable solutions for changing the direction of fluid flow while maintaining the integrity and performance of the system.

Application Of Flanged Elbow

| Oil and Gas Industry | Pipelines, refineries, and petrochemical plants. |

| Chemical Processing | Transporting corrosive and hazardous substances. |

| Power Generation | Boiler systems, steam lines, and cooling systems. |

| Water Treatment | Filtration, sedimentation, and distribution processes. |

| Food and Beverage Industry | Sanitary piping for food-grade liquids and dairy products. |

| Pharmaceutical Industry | Sterile and clean piping systems for chemicals and solvents. |

| HVAC Systems | Heating, ventilation, and air conditioning ducts and piping. |

| Marine and Offshore Applications | Ships, offshore platforms, and drilling rigs. |

| Aerospace and Defense | Hydraulic and fuel line connections in aircraft systems. |

| Automotive Industry | Exhaust systems and fluid transfer lines in vehicles. |

| Mining Industry | Slurry transport, dewatering, and ventilation in mining operations. |

| Pulp and Paper Industry | Transporting pulp, chemicals, and steam in mills. |

Frequently Asked Questions

Most frequent questions and answers