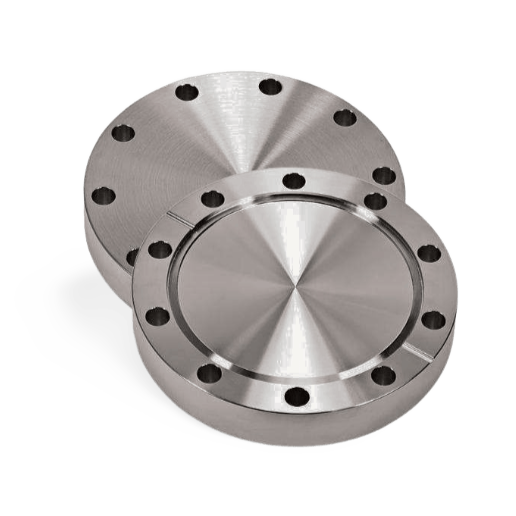

Blind Flange

Teshi Fittings, a premier manufacturer of pipe fittings, offers high-quality Blind Flanges designed for various industries including Petroleum, Chemical, Hydraulic, Food, and more. Crafted with meticulous precision and adherence to international quality standards, our Blind Flanges ensure reliable sealing and termination solutions for piping systems. With a commitment to excellence and customer satisfaction, Teshi Fittings delivers superior performance and durability in every flange, providing tailored solutions to meet specific project requirements. Experience the difference with Teshi Fittings’ Blind Flanges and trust in our expertise for all your piping needs.

Standard Specification of Blind Flange

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, ASA, API-605, MSS SP44, AWWA, Custom Drawings |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Flange Face Types / Connection Type | Flat Face Flange (FF), Raised Face Flange (RF), Ring Joint Flange (RTJ), Lap Joint Flange, Male and Female Flange (M&F), Large and Small Tongue-and-Groove Flange (T&G) |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

| Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

Material & Grades of Blind Flange

| Stainless Steel | ASTM A-479, A-182, 304, 304L,304H,304S, 316, 316L,316 Ti, 316H, 309, 310, 310S, 317L, 321, 347, 409, 410, 420, 430, 440, 446, 904L. etc. |

| Duplex & Super Duplex Steel | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 & ASTM / ASME A/SA 182, A240 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Carbon Steel | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Low Temperature Carbon Steel | ASTM A350, LF2, LF3 |

| Alloy Steel | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Nickel Alloy | Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II) |

Dimension of Blind Flange

Spectacle Blind Flange 2500 Lbs:

| PIPE SIZE | Spectacle Blinds 2500# Flange | |||||

|---|---|---|---|---|---|---|

| A | B | C | D | E | F | |

| 1/2″ | 0.625 | 2.625 | 3.5 | – | 1.50 | 3/8 |

| 3/4″ | 0.82 | 2.875 | 3.75 | 0.875 | 1.625 | 3/8 |

| 1″ | 1.05 | 3.25 | 4.25 | 1.0 | 2.5 | 3/8 |

| 1-1/4″ | 1.38 | 4.0 | 5.125 | 1.125 | 2.5 | 1/2 |

| 1-1/2″ | 1.61 | 4.5 | 5.75 | 1.25 | 2.75 | 5/8 |

| 2″ | 2.07 | 5.625 | 6.75 | 1.125 | 2.75 | 5/8 |

| 2-1/2″ | 2.47 | 6.5 | 7.75 | 1.25 | 3.0 | 3/4 |

| 3″ | 3.07 | 7.625 | 9.0 | 1.375 | 3.0 | 7/8 |

| 4″ | 4.03 | 9.125 | 10.75 | 1.625 | 3.5 | 1-1/8 |

| 5″ | 5.05 | 10.875 | 12.75 | 1.875 | 3.5 | 1-3/8 |

| 6″ | 6.06 | 12.375 | 14.5 | 2.125 | 3.5 | 2 |

| 8″ | 7.81 | 15.125 | 17.25 | 2.125 | 4.0 | 2-1/8 |

| 10″ | 9.75 | 18.625 | 21.25 | 2.625 | 4.5 | 2-5/8 |

| 12″ | 11.37 | 21.5 | 24.375 | 2.875 | 4.5 | 3-1/8 |

Spectacle Blind Flange 1500 Lbs:

| PIPE SIZE | Spectacle Blind 1500# Flanges | |||||

|---|---|---|---|---|---|---|

| A | B | C | D | E | F | |

| 1/2″ | 0.625 | 2.375 | 3.25 | – | 1.50 | 1/4 |

| 3/4″ | 0.82 | 2.625 | 3.50 | 0.875 | 1.625 | 3/8 |

| 1″ | 1.05 | 3.0 | 4.0 | 1.0 | 2.5 | 3/8 |

| 1-1/4″ | 1.375 | 3.375 | 4.375 | 1.0 | 2.5 | 3/8 |

| 1-1/2″ | 1.61 | 3.75 | 4.875 | 1.125 | 2.75 | 1/2 |

| 2″ | 2.07 | 5.5 | 6.5 | 1.0 | 2.75 | 1/2 |

| 2-1/2″ | 2.47 | 6.375 | 7.5 | 1.125 | 3.0 | 5/8 |

| 3″ | 3.07 | 6.75 | 8.0 | 1.25 | 3.0 | 3/4 |

| 4″ | 4.03 | 8.125 | 9.5 | 1.375 | 3.5 | 7/8 |

| 5″ | 5.05 | 9.875 | 11.5 | 1.625 | 3.5 | 1-1/8 |

| 6″ | 6.06 | 11.0 | 12.5 | 1.5 | 3.5 | 1-3/8 |

| 8″ | 7.98 | 13.75 | 15.5 | 1.75 | 4.0 | 1-5/8 |

| 10″ | 10.02 | 17.0 | 19.0 | 2.0 | 4.5 | 2 |

| 12″ | 11.94 | 20.375 | 22.5 | 2.125 | 4.5 | 2-3/8 |

| 14″ | 13.12 | 22.625 | 25.0 | 2.375 | 5.0 | 2-5/8 |

| 16″ | 15.0 | 25.125 | 27.75 | 2.625 | 5.25 | 3 |

| 18″ | 16.88 | 27.625 | 30.5 | 2.875 | 5.75 | 3-3/8 |

| 20″ | 18.81 | 29.625 | 32.75 | 3.125 | 6.0 | 3-3/4 |

| 24″ | 22.62 | 35.375 | 39.0 | 3.625 | 7.0 | 4-3/8 |

Spectacle Blind Flange 900 Lbs:

| PIPE SIZE | Spectacle Blind 900# Flange | |||||

|---|---|---|---|---|---|---|

| A | B | C | D | E | F | |

| 1/2″ | 0.625 | 2.375 | 3.25 | – | 1.50 | 1/4 |

| 3/4″ | 0.0825 | 2.625 | 3.50 | 0.875 | 1.625 | 1/4 |

| 1″ | 1.05 | 3.0 | 4.0 | 1.0 | 2.25 | 1/4 |

| 1-1/4″ | 1.44 | 3.375 | 4.375 | 1.0 | 2.25 | 3/8 |

| 1-1/2″ | 1.68 | 3.5 | 4.875 | 1.125 | 2.625 | 3/8 |

| 2″ | 2.16 | 5.5 | 6.5 | 1.0 | 2.25 | 1/2 |

| 2-1/2″ | 2.64 | 6.375 | 7.5 | 1.125 | 2.625 | 1/2 |

| 3″ | 3.25 | 6.5 | 7.5 | 1.0 | 2.625 | 5/8 |

| 4″ | 4.25 | 8.0 | 9.25 | 1.25 | 3.0 | 3/4 |

| 5″ | 5.3 | 9.625 | 11.0 | 1.375 | 3.375 | 7/8 |

| 6″ | 6.36 | 11.25 | 12.5 | 1.25 | 3.375 | 1 |

| 8″ | 8.33 | 14.0 | 15.5 | 1.5 | 3.75 | 1-3/8 |

| 10″ | 10.42 | 17.0 | 18.5 | 1.5 | 4.125 | 1-5/8 |

| 12″ | 12.39 | 19.5 | 21.0 | 1.5 | 4.125 | 1-7/8 |

| 14″ | 13.62 | 20.375 | 22.0 | 1.625 | 4.5 | 2-1/8 |

| 16″ | 15.62 | 22.5 | 24.25 | 1.75 | 4.875 | 2-3/8 |

| 18″ | 17.62 | 25.0 | 27.0 | 2.0 | 5.25 | 2-5/8 |

| 20″ | 19.56 | 27.375 | 29.5 | 2.125 | 5.25 | 2-7/8 |

| 24″ | 23.5 | 32.875 | 35.5 | 2.625 | 6.0 | 3-1/2 |

Spectacle Blind Flange 600 Lbs:

| PIPE SIZE | Spectacle Blind 600# Flange | |||||

|---|---|---|---|---|---|---|

| A | B | C | D | E | F | |

| 1/2″ | 5/8 | 2 | 2-5/8 | 5/8 | 1-1/2 | 1/4 |

| 3/4″ | 13/16 | 2-1/2 | 3-1/4 | 3/4 | 1-1/2 | 1/4 |

| 1″ | 1-1/8 | 2-3/4 | 3-1/2 | 3/4 | 2-1/4 | 1/4 |

| 1-1/4″ | 1-7/16 | 3-1/8 | 3-7/8 | 3/4 | 2-1/4 | 3/8 |

| 1-1/2″ | 1-11/16 | 3-5/8 | 4-1/2 | 7/8 | 2-5/8 | 3/8 |

| 2″ | 2-1/8 | 4-1/4 | 5 | 3/4 | 2-1/4 | 3/8 |

| 2-1/2″ | 2-5/8 | 5 | 5-7/8 | 7/8 | 2-5/8 | 1/2 |

| 3″ | 3-1/4 | 5-3/4 | 6-5/8 | 7/8 | 2-5/8 | 1/2 |

| 3-1/2″ | 3-3/4 | 6-1/4 | 7-1/4 | 1 | 3 | 5/8 |

| 4″ | 4-1/4 | 7-1/2 | 8-1/2 | 1 | 3 | 5/8 |

| 5″ | 5-1/4 | 9-3/8 | 10-1/2 | 1-1/8 | 3-3/8 | 3/4 |

| 6″ | 6-3/8 | 10-3/8 | 11-1/2 | 1-1/8 | 3-3/8 | 7/8 |

| 8″ | 8-3/8 | 12-1/2 | 13-3/4 | 1-1/4 | 3-3/4 | 1-1/8 |

| 10″ | 10-7/16 | 15-5/8 | 17 | 1-3/8 | 4-1/8 | 1-3/8 |

| 12″ | 12-3/8 | 17-7/8 | 19-1/4 | 1-3/8 | 4-1/8 | 1-5/8 |

| 14″ | 13-5/8 | 19-1/4 | 20-3/4 | 1-1/2 | 4-1/2 | 1-3/4 |

| 16″ | 15-5/8 | 22-1/8 | 23-3/4 | 1-5/8 | 4-7/8 | 2 |

| 18″ | 17-5/8 | 24 | 25-3/4 | 1-3/4 | 5-1/4 | 2-1/8 |

| 20″ | 19-5/16 | 26-3/4 | 28-1/2 | 1-3/4 | 5-1/4 | 2-1/2 |

| 24″ | 23-1/2 | 31 | 33 | 2 | 6 | 2-7/8 |

Spectacle Blind Flange 300 Lbs:

| PIPE SIZE | Spectacle Blind 300# Flange | |||||

|---|---|---|---|---|---|---|

| A | B | C | D | E | F | |

| 1/2″ | 5/8 | 2 | 2-5/8 | 5/8 | 1-1/2 | 1/4 |

| 3/4″ | 13/16 | 2-1/2 | 3-1/4 | 3/4 | 1-1/2 | 1/4 |

| 1″ | 1-1/8 | 2-3/4 | 3-1/2 | 11/16 | 1-1/2 | 1/4 |

| 1-1/4″ | 1-5/8 | 3-1/8 | 3-7/8 | 11/16 | 1-1/2 | 1/4 |

| 1-1/2″ | 1-7/8 | 3-5/8 | 4-1/2 | 7/8 | 2 | 1/4 |

| 2″ | 2-3/8 | 4-1/4 | 5 | 3/4 | 2 | 3/8 |

| 2-1/2″ | 2-7/8 | 5 | 5-7/8 | 7/8 | 2-1/2 | 3/8 |

| 3″ | 3-1/2 | 5-3/4 | 6-5/8 | 7/8 | 2-1/2 | 3/8 |

| 3-1/2″ | 4 | 6-3/8 | 7-1/4 | 7/8 | 2-1/2 | 1/2 |

| 4″ | 4-1/2 | 7 | 7-7/8 | 7/8 | 2-1/2 | 1/2 |

| 5″ | 5-5/8 | 8-3/8 | 9-1/4 | 7/8 | 3 | 5/8 |

| 6″ | 6-5/8 | 9-3/4 | 10-5/8 | 7/8 | 3 | 5/8 |

| 8″ | 8-5/8 | 12 | 13 | 1 | 3-1/2 | 7/8 |

| 10″ | 10-3/4 | 14-1/8 | 15-1/4 | 1-1/8 | 4 | 1 |

| 12″ | 12-3/4 | 16-1/2 | 17-3/4 | 1-1/4 | 4 | 1-1/8 |

| 14″ | 14 | 19 | 20-1/4 | 1-1/4 | 4-3/4 | 1-1/4 |

| 16″ | 16 | 21-1/8 | 22-1/2 | 1-3/8 | 4-7/8 | 1-1/2 |

| 18″ | 18 | 23-3/8 | 24-3/4 | 1-3/8 | 4-1/2 | 1-5/8 |

| 20″ | 20 | 25-5/8 | 27 | 1-3/8 | 4-3/4 | 1-3/4 |

| 24″ | 24 | 30-3/8 | 32 | 1-5/8 | 5-1/2 | 2 |

Spectacle Blind Flange 150 Lbs:

| PIPE SIZE | Spectacle Blind 150# Flange | |||||

|---|---|---|---|---|---|---|

| A | B | C | D | E | F | |

| 1/2″ | 5/8 | 1-3/4 | 2-3/8 | 5/8 | 1-1/2 | 1/4 |

| 3/4″ | 13/16 | 2-1/8 | 2-3/4 | 5/8 | 1-1/2 | 1/4 |

| 1″ | 1-1/8 | 2-1/2 | 3-1/8 | 9/16 | 1-1/2 | 1/4 |

| 1-1/4″ | 1-5/8 | 2-7/8 | 3-1/2 | 9/16 | 1-1/2 | 1/4 |

| 1-1/2″ | 1-7/8 | 3-1/4 | 3-7/8 | 9/16 | 1-1/2 | 1/4 |

| 2″ | 2-3/8 | 4 | 4-3/4 | 11/16 | 2 | 1/4 |

| 2-1/2″ | 2-7/8 | 4-3/4 | 5-1/2 | 11/16 | 2 | 1/4 |

| 3″ | 3-1/2 | 5-1/4 | 6 | 11/16 | 2-1/2 | 1/4 |

| 3-1/2″ | 4 | 6-1/4 | 7 | 3/4 | 2-1/2 | 3/8 |

| 4″ | 4-1/2 | 6-3/4 | 7-1/2 | 3/4 | 2-1/2 | 3/8 |

| 5″ | 5-9/16 | 7-5/8 | 8-1/2 | 7/8 | 3 | 3/8 |

| 6″ | 6-5/8 | 8-5/8 | 9-1/2 | 7/8 | 3 | 1/2 |

| 8″ | 8-5/8 | 10-7/8 | 11-3/4 | 7/8 | 3 | 1/2 |

| 10″ | 10-3/4 | 13-1/4 | 14-1/4 | 1 | 4 | 5/8 |

| 12″ | 12-3/4 | 16 | 17 | 1 | 4 | 3/4 |

| 14″ | 14 | 17-5/8 | 18-3/4 | 1-1/8 | 4-1/4 | 3/4 |

| 16″ | 16 | 20-1/8 | 21-1/4 | 1-1/8 | 4-1/4 | 7/8 |

| 18″ | 18 | 21-1/2 | 22-3/4 | 1-1/4 | 4-1/2 | 1 |

| 20″ | 20 | 23-3/4 | 25 | 1-1/4 | 4-3/4 | 1-1/8 |

| 24″ | 24 | 28-1/8 | 29-1/2 | 1-3/8 | 5-1/2 | 1-1/4 |

Manufacturing process and features of Blind Flange

A Blind Flange is a type of pipe fitting used to close the end of a piping system or pressure vessel openings. It allows for the secure sealing of pipelines, providing an essential function in various industrial applications. Here’s an overview of its manufacturing process and features:

Manufacturing Process:

- Material Selection : Choose appropriate materials like carbon steel, stainless steel, or alloy steel based on application requirements.

- Cutting : Raw material is cut to the required size using a cutting machine or torch.

- Forging : The cut material is heated and forged into shape under high pressure to improve strength and grain structure.

- Machining : The forged piece is machined to precise dimensions using CNC machines, ensuring the flange meets specified tolerances.

- Drilling : Bolt holes are drilled as per flange standards like ANSI B16.5, ensuring accurate alignment for bolting.

- Heat Treatment : The flange undergoes heat treatment processes like annealing, normalizing, or quenching to enhance mechanical properties.

- Surface Finishing : The flange surface is finished by processes like sandblasting or polishing to remove any impurities and improve appearance.

- Inspection and Testing : Non-destructive tests (NDT) such as ultrasonic testing, radiographic testing, or magnetic particle inspection are conducted to ensure the integrity and quality of the flange.

- Marking : The flange is marked with relevant specifications, such as material grade, size, pressure rating, and standard.

- Packaging : The finished flanges are carefully packaged to prevent damage during transportation.

Features of Blind Flange:

- Sealability : Designed to provide a secure seal, preventing leakage in piping systems.

- Versatility : Suitable for a wide range of applications in various industries, including oil and gas, chemical, power, and water supply.

- Strength : Forged from high-quality materials, ensuring durability and the ability to withstand high pressure and temperature.

- Precision : Manufactured to exact dimensions and tolerances, ensuring proper fit and alignment with other piping components.

- Corrosion Resistance : Available in materials that offer excellent resistance to corrosion and wear, enhancing longevity in harsh environments.

- Customizability : Can be manufactured in various sizes, materials, and pressure ratings to meet specific application requirements.

- Ease of Installation : Designed for easy installation and removal, facilitating maintenance and modifications in piping systems.

- Standards Compliance : Produced in accordance with international standards like ANSI, ASME, and ASTM, ensuring compatibility and reliability.

- Cost-Effectiveness : Provides an economical solution for sealing the ends of pipes, especially in systems that may require future expansion or modifications.

- Safety : Enhances the safety of piping systems by providing a reliable means of isolating sections for maintenance and repairs.

Blind Flanges are essential fittings that provide reliable sealing in piping systems. They offer durability, versatility, and ease of installation, making them suitable for a wide range of industrial applications.

Application Of Blind Flanges

| Oil and Gas | Stainless Steel Blind Flanges: Used to cap off pipelines, providing a secure and leak-proof seal in oil and gas transportation systems. |

| Chemical Industry | Blind Raised Face Flanges: Employed to isolate sections of piping systems during maintenance or modifications, ensuring safe handling of chemicals. |

| Plumbing | Alloy Steel BLRF Flanges: Used in plumbing systems to close off unused openings and prevent leakage. |

| Heating Systems | Flat Faced Blind Flanges: Utilized in heating systems to block off the ends of pipes, ensuring efficient and safe operation. |

| Water Supply | Blind Pipe Flanges: Applied to seal off water supply pipelines, maintaining pressure and preventing leaks. |

| Power Plants | ANSI B16.5 Blind Forged Flanges: Essential in power plants for sealing high-pressure and high-temperature piping systems, ensuring safety and reliability. |

| Paper & Pulp | Blind Plate Flanges: Used to block off sections of piping in paper and pulp processing, allowing for maintenance and modifications without disrupting operations. |

| General Use | Blind Flanges: Widely used to seal off piping systems in various general-purpose applications, providing flexibility and safety. |

| Fabrication | Steel Blind Flanges: Utilized in the fabrication of structures and piping systems, providing secure closures and ease of access for future modifications. |

| Food Processing | Blind Flange: Used to seal off sanitary piping systems, ensuring hygiene and preventing contamination in food processing applications. |

| Structural Pipes | Blind Flanges: Applied to close off structural pipes, ensuring stability and preventing ingress of foreign materials. |

Blind Flange Available Types

| Blind Flange Manufacturer | Blind Flange Exporter |

| Stainless Steel Blind Flange | Forged Steel Raised Face Blind Flange |

| Carbon Steel Blind Flange | ANSI B16.47 Blind Flange |

| Alloy Steel Blind Flange Stockholder | Class 150 LBS Blind Flange Stockiest |

| Nickel Alloy Blind Flange Suppliers | MSS SP44 Blind Flange |

| Inconel Blind Flange Stockiest | Class 300 LBS Blind Flange |

| Alloy Steel Blind Flange Exporter | Class 600 LBS Blind Flange |

| Duplex Steel Blind Flange Stockists | DIN / EN Blind Flange Manufacturers |

| Titanium Alloy Blind Flange | ASME / ANSI B16.5 BLRF Flange |

| Super Duplex Steel BLRF Flange | ANSI / ASME Blind Flange |

| Copper Nickel Blind Flange | High Quality Blind Flange |

Others Products

Frequently Asked Questions

Most frequent questions and answers