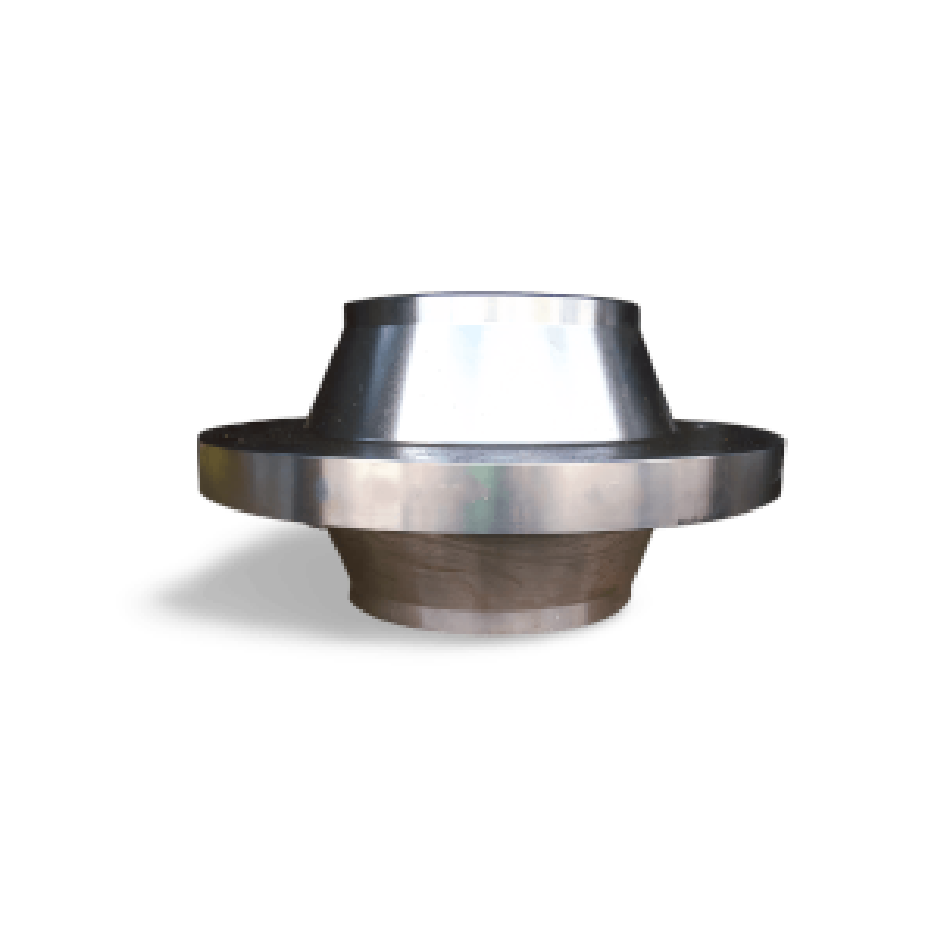

Anchor Flanges

Teshi Fittings, a premier manufacturer of pipe fittings, offers high-quality Anchor Flanges designed for various industries including Petroleum, Chemical, Hydraulic, Food, and more. Crafted with meticulous precision and adherence to international quality standards, our Anchor Flanges provide secure and stable connections for piping systems, preventing movement and ensuring structural integrity. With a commitment to excellence and customer satisfaction, Teshi Fittings delivers superior performance and durability in every flange, offering tailored solutions to meet specific project requirements. Experience the difference with Teshi Fittings’ Anchor Flanges and trust in our expertise for all your piping needs.

Standard Specification of Anchor Flanges

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, ASA, API-605, MSS SP44, AWWA, Custom Drawings |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Flange Face Types / Connection Type | Flat Face Flange (FF), Raised Face Flange (RF), Ring Joint Flange (RTJ), Lap Joint Flange, Male and Female Flange (M&F), Large and Small Tongue-and-Groove Flange (T&G) |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

| Class / Pressure Rating | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

Material & Grades of Anchor Flanges

| Stainless Steel | ASTM A-479, A-182, 304, 304L,304H,304S, 316, 316L,316 Ti, 316H, 309, 310, 310S, 317L, 321, 347, 409, 410, 420, 430, 440, 446, 904L. etc. |

| Duplex & Super Duplex Steel | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 & ASTM / ASME A/SA 182, A240 F 44, F 45, F51, F 53, F 55, F 60, F 61 |

| Carbon Steel | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Low Temperature Carbon Steel | ASTM A350, LF2, LF3 |

| Alloy Steel | ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91 |

| Nickel Alloy | Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II) |

Dimension of Anchor Flanges

| NPS (Normal Pipe Size) | Daimeter Of Bore | Pre Beveled Hub Daimeter | For 40%F Temperature Change | For 90%F Temperature Change | ||||||

| Daimeter O | Daimeter Q | Daimeter L | Daimeter X | Daimeter O | Daimeter Q | Daimeter L | Daimeter X | |||

| 6 | 6.75 | 9.5 | 0.63 | 2.88 | 7 | 11.25 | 1.13 | 3.63 | 7 | |

| 8 | 8.75 | 12.13 | 0.75 | 3 | 9 | 14.63 | 1.38 | 3.88 | 9 | |

| 10 | 11 | 14.88 | 0.88 | 3.13 | 11.13 | 17.13 | 1.5 | 4 | 11.13 | |

| 12 | 13 | 17.75 | 1 | 3.5 | 13.25 | 19.25 | 1.63 | 4.25 | 13.25 | |

| 14 | 14.25 | 19.63 | 1.13 | 3.75 | 14.5 | 20.5 | 1.75 | 4.5 | 14.5 | |

| 16 | 16.25 | 22.38 | 1.31 | 4.19 | 16.3 | 22.5 | 1.81 | 5 | 16.63 | |

| 18 | 18.25 | 24.63 | 1.38 | 4.63 | 18.63 | 24.63 | 1.94 | 5.5 | 78.63 | |

| 20 | 20.31 | 26.63 | 1.5 | 4.88 | 20.63 | 26.75 | 2 | 6 | 20.75 | |

| 22 | 22.31 | 28.63 | 1.63 | 5.13 | 22.63 | 28.75 | 2.13 | 6.25 | 22.75 | |

| 24 | 24.38 | 30.63 | 1.69 | 5.44 | 24.63 | 31 | 2.25 | 6.75 | 24.88 | |

| 26 | 26.38 | 32.75 | 1.75 | 5.88 | 16.75 | 32.88 | 2.31 | 7.13 | 26.88 | |

| 28 | 28.38 | 34.88 | 1.81 | 6.19 | 28.88 | 35 | 2.38 | 7.5 | 29 | |

| 30 | 30.44 | 36.88 | 1.94 | 6.56 | 30.88 | 37 | 2.5 | 8 | 31 | |

| 34 | 34.5 | 41 | 2.06 | 7.19 | 35 | 41 | 2.75 | 8.75 | 35 | |

| 36 | 36.5 | 43 | 2.13 | 8 | 37 | 43 | 2.88 | 9.63 | 37 | |

Manufacturing process and features of Anchor Flanges

Manufacturing Process:

- Material Selection : Choose suitable materials such as carbon steel, stainless steel, or alloy steel based on the application requirements. The material must ensure the flange’s strength, durability, and resistance to environmental conditions.

- Cutting : Raw materials are cut into specific shapes and sizes using methods like sawing, laser cutting, or water jet cutting. This forms the initial blank for the anchor flange.

- Forging : The cut blanks are heated and forged under high pressure to shape the flange. Forging enhances the material’s grain structure, resulting in improved strength and structural integrity.

- Machining : The forged blanks are machined to precise dimensions using CNC machines or other precision machining tools. This process includes creating the flange face, boring the central hole, and drilling bolt holes according to the required specifications.

- Welding : Anchor flanges often require additional welding processes to attach the anchor or reinforcement components. High-quality welds ensure the structural integrity of the flange.

- Heat Treatment : Depending on the material and application, the flanges may undergo heat treatment processes such as annealing, quenching, and tempering to enhance mechanical properties like toughness and hardness.

- Surface Treatment : Apply surface treatments such as galvanizing, painting, or coating to improve corrosion resistance and aesthetic appeal.

- Inspection and Quality Control : Flanges undergo rigorous quality control checks, including dimensional inspections, pressure testing, and material verification, to ensure they meet industry standards and specifications.

- Marking and Packaging : Approved flanges are marked with essential information such as size, material grade, pressure rating, and standards. They are then packaged for storage and transportation.

Features of Anchor Flanges :

- High Strength : Manufactured from robust materials and enhanced through forging and heat treatment, anchor flanges exhibit high strength to withstand significant forces.

- Secure Anchorage : Designed to provide a stable anchor point in piping systems, preventing movement and ensuring system stability under pressure.

- Corrosion Resistance : Depending on the material and surface treatment, anchor flanges offer excellent resistance to corrosion, making them suitable for harsh environments.

- Leak-Free Connections : Precision machining and high-quality welding ensure leak-free connections, reducing the risk of fluid leakage and maintaining system integrity.

- Durability : Built to last, with high-quality materials and manufacturing processes ensuring long-term performance and reliability.

- Standard Compliance : Manufactured to comply with industry standards such as ANSI, ASME, and API, ensuring compatibility and reliability in various applications.

- Ease of Installation : Designed for straightforward installation with precise dimensions for easy alignment during assembly.

- Versatility : Suitable for various applications and environments, available in different sizes and material grades to meet specific requirements.

Anchor flanges are essential components in many industrial applications, providing reliable and durable anchorage points in piping systems. Their robust construction and versatile features make them a preferred choice for maintaining system stability and integrity under demanding conditions.

Application Of Anchor Flanges

| Oil and Gas Industry | Pipeline Systems: Used to secure pipelines in place, preventing axial movement due to internal pressure or external forces. Offshore Platforms: Essential in stabilizing piping systems in offshore drilling and production facilities. |

| Petrochemical Industry | Refineries: Employed to anchor piping systems that transport various chemicals and hydrocarbons, ensuring stability under varying pressures and temperatures. Chemical Plants: Used in processes where high-pressure and high-temperature fluids are handled, preventing pipe displacement. |

| Power Generation | Thermal Power Plants: Anchor flanges stabilize steam and water pipelines, ensuring efficient and safe operation of boilers and turbines. Nuclear Power Plants: Critical for securing piping systems that carry coolant and other critical fluids. |

| Water Treatment | Water Distribution Systems: Used to anchor large-diameter pipelines in water treatment plants and distribution networks. Sewage Treatment: Stabilize pipes in wastewater treatment facilities, ensuring reliable flow and preventing pipe movement. |

| Construction and Infrastructure | Bridges and Tunnels: Employed in securing pipelines that run through bridges and tunnels, preventing displacement due to vibrations or structural movements. Buildings: Used in HVAC systems to anchor piping that distributes heating and cooling fluids. |

| Marine and Shipbuilding | Ships: Stabilize piping systems on ships, preventing movement due to the motion of the vessel. Offshore Structures: Used in floating production storage and offloading (FPSO) units and other marine applications. |

| Mining Industry | Ore Processing Plants: Anchor flanges secure pipelines transporting slurry and other mining by-products. Mine Ventilation Systems: Stabilize air ducts and piping systems in underground mines. |

| Food and Beverage Industry | Processing Plants: Used to stabilize piping systems that transport liquids and gases in food and beverage manufacturing. Dairy Industry: Ensures stable connections in pipelines carrying milk and other dairy products. |

| Pharmaceutical Industry | Manufacturing Facilities: Anchor flanges stabilize piping systems that handle various pharmaceutical ingredients and products, ensuring precise and contamination-free operations. |

| HVAC Systems | Heating and Cooling Systems: Used to anchor pipes in HVAC systems, preventing movement due to thermal expansion or external forces. |

| Chemical Processing | Production Lines: Stabilize pipes that transport reactive and corrosive chemicals, ensuring safety and efficiency in chemical processes. |

| Aerospace and Defense | Fuel and Hydraulic Systems: Secure pipelines in aerospace applications, ensuring reliable and stable fluid transport under varying pressures and temperatures. |